- Email us at:info@misterconcrete.co.uk

Underfloor heating (UFH) is a great way to warm your home efficiently, as it heats the room evenly and requires less energy to reach the desired temperature. If you're planning to install UFH, you'll need to choose a screed mix that will cover it. In this article, we'll discuss the factors to consider, the necessary preparation, and how to get the most out of your UFH by selecting the best screed.

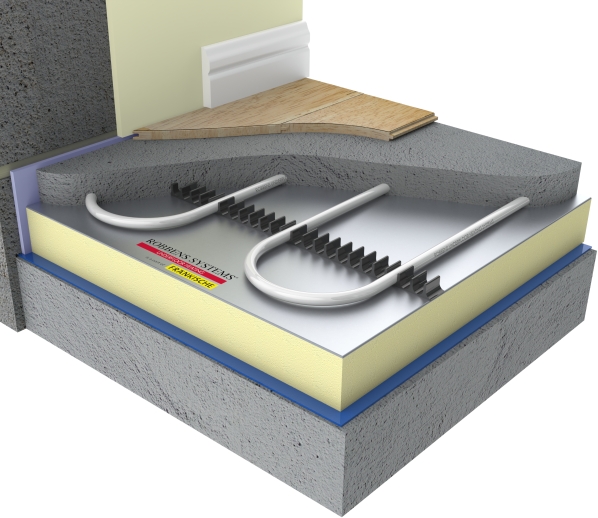

Types of underfloor heating systems

There are two main types of UFH: warm water and electric. Warm water UFH circulates warm water through steel, copper, or PVC pipes that are evenly distributed across the floor. Electric UFH uses electrical cables, which are less efficient and typically only used in small spaces such as bathrooms.

Installation

To install UFH, the subfloor (a concrete slab or a beam & block) is first insulated with a waterproof membrane, a thermal insulation layer (such as polystyrene or mineral wool), and possibly a vapor insulation layer. The pipes are then fitted to the underlay using clips. Once everything is prepared, the ready mix screed is placed and allowed to dry, after which the flooring of your choice can be installed.

The thickness of screed to use

The recommended thickness of the screed covering the pipes is important, as it affects how the UFH distributes heat. For traditional sand cement screed, a thickness of 65-75 mm is recommended. For screed with additives such as fiber (which makes the screed stronger), a minimum thickness of 50 mm can be used. The same guidelines apply to both ground and upper-level floors.

Types of screed used for UFH

There are two main types of screed used for underfloor heating (UFH) systems: dry screeds and self-leveling screeds. Dry screeds are the more traditional option and are typically used in smaller areas. They are made by mixing cement and sand in a 1:3-5 ratio, along with water and fiber additives to prevent cracking. Other additives may also be added to speed up drying time. Self-leveling screeds, also known as liquid screeds or flowing screeds, are made of calcium sulfate, sand, water, and other chemicals. They are poured or pumped onto the area and spread to the desired level on their own. Self-leveling screeds are typically used in larger industrial or commercial areas and are more expensive than dry screeds.

Source: https://www.underfloorheating.co.uk

Can I use any flooring when using UFH?

As long as the underlay and UFH are installed properly and certain conditions are met, any type of flooring can be used over UFH. Ceramic and natural stone tiles, PVC, and textile flooring have high thermal conductivity and are the best choices for use with UFH. Wood is the least preferred option, but it can still be used as a floating floor with a special board or by gluing directly to the substrate with a polyurethane adhesive. Always follow the manufacturer's instructions for your specific flooring choice.

If you need a ready mix concrete screed delivered to your site, please contact us for a free price estimate.

categories

latest posts

services

Mister Concrete serves domestic, commercial and industrial clients delivering high quality certified ready mix and onsite mixed concrete.

Get in touch with us now

Do not hesitate to use our contact form or give us a call and one of our professionals will be happy to help.

comments